In a quiet corner of Brazil, engineers and mathematicians have stitched together a method that lets them model rotationally symmetric objects with remarkable flexibility. The study, conducted by researchers at the Escola Politécnica of the University of São Paulo, shines a light on how the Virtual Element Method (VEM) can be bundled with axisymmetry to turn three-dimensional intuition into a two-dimensional computation without losing the physics. The authors, Paulo Akira F. Enabe and Rodrigo Provasi, show that by embracing the geometry’s natural symmetry, you can simplify the problem — and still keep the full story of how a solid deforms under load. What sounds technical in a powdery mathematics paper becomes a practical tool for designers who work with pipes, shells, and tanks that spin or stand upright under pressure.

Two ideas sit at the heart of this work. First, axisymmetry — the fact that a body and its loading don’t change when you twist around a central axis — lets you reduce a three-dimensional problem to a meridional cross-section, a plane that carries all the essential information. Second, VEM, a newer cousin of the finite element method, lets you mesh oddly shaped polygons without the usual headache of building interior shape functions. Put together, they form a framework that respects the physics (the weight of the cylindrical geometry, the way hoop stress interacts with radial displacement), while granting engineers the freedom to use general meshes that fit real-world geometries. The paper is not just a proof of concept; it’s a carefully engineered bridge between mathematical rigor and practical simulation for axisymmetric elasticity.

One standout feature the authors emphasize is physical fidelity inside the axisymmetric world. In cylindrical coordinates, the volume element isn’t simply dx dy; it carries a weight r that grows with the radius. That simple geometric fact cascades into how energies are computed and how stresses talk to strains. The team’s formulation weaves this radial weighting into every integral, ensuring that a two-dimensional cross-section really does represent the full three-dimensional body when you weave it back along the circle. They also introduce a boundary-centered projection that maps virtual (in-principle unknown) displacements onto a space of constant strains, plus a volumetric correction that accounts for the ever-present hoop-radial tension interplay. It sounds abstract, but the payoff is a framework that remains stable and accurate even on meshes that would flummox traditional methods.

From cylinders to cross-sections

Axisymmetry isn’t just a mathematical nicety; it’s a practical lens. When a problem’s geometry and loading don’t change with the azimuthal angle, θ, you can slice the world along the plane defined by radius r and height z and drop the third dimension from your equations. The displacement field collapses to two components: ur(r, z) in the radial direction and uz(r, z) along the axis. The calculus, however, doesn’t collapse so neatly. The hoop strain, εθθ, refuses to vanish and is tied to ur by the relation εθθ = ur/r. That simple 1/r factor is a stubborn reminder that cylindrical coordinates aren’t a cosmetic rearrangement of Cartesian space; they’re a lived geometry whose volume element carries weight r, and whose energy terms are then weighted accordingly.

In the paper’s weak form, this weighting shows up explicitly. The bilinear form that represents the material’s elastic energy includes an integral over the domain with the r weight, and boundary terms also carry that factor to reflect the true surface measure in a cylinder. The authors don’t shy away from the coupling this geometry creates: hoop stress, which arises because a ring wants to expand as it’s pulled, feeds back into the balance of forces in the radial and axial directions. The result is a formulation that respects the axisymmetric symmetry while preserving the integrity of the underlying physics. It’s a nice reminder that sometimes the right coordinate system isn’t just a convenience; it’s a compass that keeps the physics pointed in the right direction.

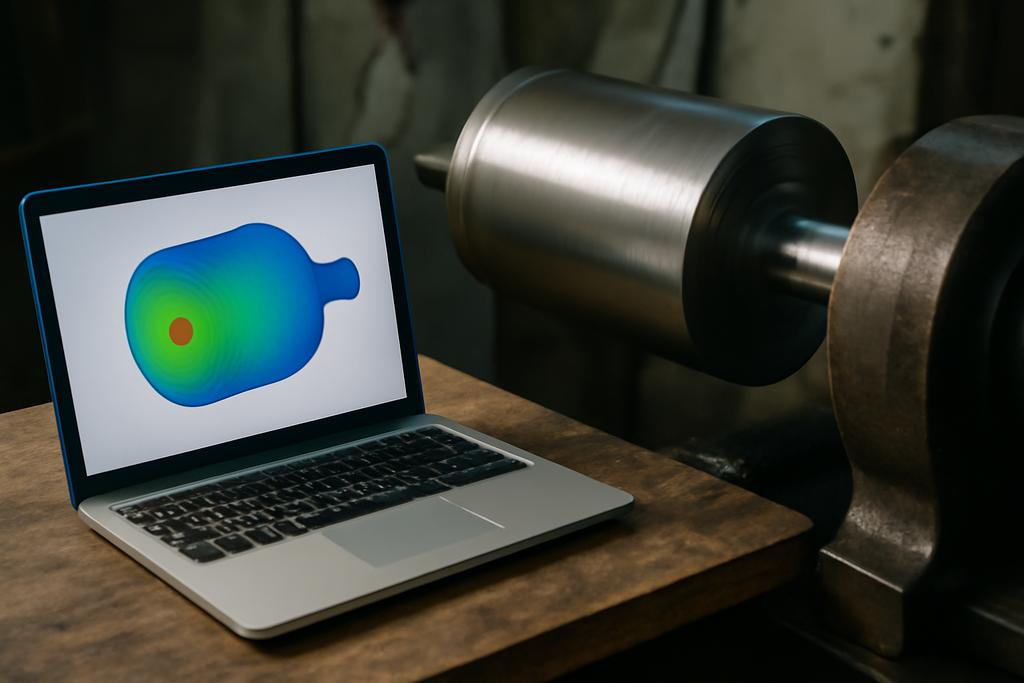

All of this matters because engineers routinely design and analyze axisymmetric structures: pressure vessels, pipelines with complex cross-sections, shells wrapped around cylinders, centrifuge components, and turbines. Traditional methods can cough when faced with curved geometries or nonstandard meshes, forcing tempting compromises between mesh quality and fidelity. The Enabe–Provasi work argues that you don’t need to abandon flexibility to keep accuracy; with axisymmetric VEM, you can have both. The study also makes a concrete contribution by presenting a method that is robust on polygonal meshes, which are inherently more forgiving when you’re trying to fit a complex boundary or a perforation. And because this is about a real institution — the University of São Paulo’s Escola Politécnica — there’s a clear path from academic insight to industrial practice, where engineers often juggle geometry, loads, and a tight timeline.

A new mesh for messy shapes

Virtual Element Method, or VEM, is a philosophical cousin of the finite element method that shares its goal — turning a physical problem into a solvable set of equations — but not its contours. Instead of explicitly building shape functions inside each polygonal element, VEM works with spaces whose interior is only implicitly defined. What you do know are the degrees of freedom on the element’s boundary and how those boundary values project onto a space of polynomials. The genius is that you can still assemble a stiff system with the same convergence guarantees as traditional FEM, even when your mesh looks like a patchwork quilt of arbitrary polygons or non-convex shapes. The axisymmetric twist in this paper hinges on how those projections and stabilizations are adapted to cylindrical symmetry and the radial weight.

The core technical move is a projection operator, Π∇, that maps a virtual displacement field into a space of constant strain fields while remaining computable solely from boundary data. The projection is not just a mathematical convenience; it’s the engine that makes the element’s contribution to stiffness consistent with axisymmetric elasticity. The authors describe a two-pronged condition: the projected gradient should reproduce bilinear forms against constant-strain polynomials, and the projection should preserve the mean value to respect the element’s overall deformation. This ensures that the energy stored in an element is represented faithfully, even though the interior function is not known in closed form. In practice, the projection matrix B and its companion, the stabilization term, act together to tame spurious internal modes that could otherwise destabilize the computation.

Stabilization in VEM is a delicate business. It must damp non-polynomial components without muting the polynomial part that carries the physical signal. Here, the stabilization is designed to act on the kernel of the projection and is constructed from boundary integrals. The boundary-based philosophy is elegant: your numerical control points are the element’s edges, not its hidden interior. This makes the method more robust on irregular meshes and easier to implement in software pipelines that favor boundary data. The paper even prescribes a concrete, edge-focused quadrature scheme, including how to handle the r-weight when integrating along a boundary where r varies. It’s a practical recipe for turning a polygonal mesh into a faithful numerical mirror of axisymmetric elasticity.

Beyond the projection and stabilization, the authors introduce a volumetric correction term to account for divergence effects that arise specifically because curvature and hoop stresses interact in the axisymmetric setting. They show how to compute this correction by decomposing the integral and using a boundary-based quadrature to approximate the interior divergence contributions. Again, the emphasis is on boundary data and a decomposition that keeps the interior’s influence computable without explicit interior shape functions. All of these pieces come together in a cohesive framework that supports general polygonal meshes while preserving the axisymmetric physics. That combination — axisymmetry plus polygonal flexibility plus a rigorous stability backbone — is what makes this work stand out as more than just an incremental tweak to VEM.

Why this could reshape engineering simulations

The practical implications are easy to underestimate until you see what it enables. For engineers, the leap is not just about a fancy numerical method; it’s about being able to mesh complex axisymmetric objects without contorting their geometry into stubborn, overly regular shapes. In the real world, you don’t design a perfect cylinder with perfectly matching edges. You sketch pipes with flanges, shells with cutouts, and vessels with ports. The axisymmetric VEM described in this paper embraces that messiness while maintaining mathematical guarantees. It means you can simulate a pressure vessel with a jagged boundary, or a shell with a perforation, and still trust the computed displacements and stresses to be reliable. That’s a practical edge: better geometry, better decisions, fewer redesign iterations.

Another virtue is the method’s compatibility with a priori error estimates in weighted Sobolev spaces. The radial weight, the axisymmetric trace inequalities, and the norm equivalence in the stabilization all feed into concrete predictions of how the error scales with mesh size. In plain terms, you get a roadmap for how fine your mesh needs to be to achieve a desired accuracy, and you know where the method might require extra attention — for instance, near the axis or in regions where hoop and radial stresses interact most strongly. This is not mere theory; it’s a guide for making simulations cost-effective without sacrificing trust in the results. The authors’ patch tests, designed to probe fundamental strain states, are more than ceremonial checks. They illuminate where the method shines and where axisymmetry’s quirks push for deeper refinement in the mathematical treatment of certain strain components.

There’s a telling nuance in the patch-test results. The radial and axial strains behaved exactly as one would want in most tests, and the shear strain matched expectations, confirming the boundary-based stabilization does its job. The hoop strain, however, exposed a subtle yet important reality: in axisymmetric elasticity, εθ = ur/r, which means attempting to prescribe a pure hoop strain in isolation nudges radial strain into play, even in idealized tests. The authors interpret this not as a failure but as a physical reminder of the geometric coupling baked into cylindrical coordinates. It’s a prompt for future refinement, not a verdict on the method’s validity. A practical takeaway is that engineers should anticipate and plan for such couplings when deploying axisymmetric VEM in design work, especially for thin shells or vessels where hoop effects loom large.

Looking ahead, the axisymmetric VEM framework opens doors to nonlinear extensions, time-dependent problems, and higher-order approximations on polygonal meshes. Imagine coupling this approach with materials that show plasticity or viscoelasticity, or with transient loads that come from earthquakes or rotating machinery. The curved geometries of real components — from pressure vessel heads to turbine casings — become more tractable when the mesh isn’t forced into a stiff, regular grid. The University of São Paulo team’s emphasis on a boundary-based, projection-driven core suggests a path toward software tools that can adaptively refine where needed, while preserving stability and consistency elsewhere. In short, the work doesn’t just solve a problem; it redefines what counts as a practical, robust numerical trick for axisymmetric solid mechanics.

Where the dream meets the daguerreotype of reality

As with many good advances in numerical analysis, the real value of axisymmetric VEM lies at the intersection of theory and practice. The authors provide a rigorous a priori error analysis in a weighted setting, establishing convergence rates that researchers can rely on when pushing mesh refinement or extending the method to new material models. They also deliver a clear implementation blueprint: how to construct the projection matrix, how to assemble the stabilization from boundary data, and how to compute the volumetric correction in a way that fits general polygonal meshes. These aren’t abstract exercises; they’re instructions for turning a mathematical idea into a tool you’d actually wire into a simulation package, test, and deploy on a geometry that would otherwise trip up conventional methods.

It’s tempting to think of axisymmetric problems as a narrow niche, but they are, in fact, a broad spectrum of real-world engineering challenges. The axisymmetric VEM framework invites better, faster, more flexible simulations for pressure vessels that must be modeled with ports and cutouts; for shells that must hold up under long-term loads; for rotating machines where the geometry is both symmetric and irregular. As computational power grows and designers demand more accurate models without ballooning meshing costs, the ability to work with polygonal meshes while preserving axisymmetric physics becomes an attractive combination. In that sense, Enabe and Provasi help bridge a gap between mathematical elegance and engineering practicality. The work is a reminder that the most useful numerical methods are laser-focused on the messy, imperfect shapes that engineers actually encounter, not only the idealized specimens that live in textbooks.

Of course, like any nascent approach, the axisymmetric VEM has its live questions. The patch tests reveal that while radial and axial components can be captured with machine-like precision, hoop strain remains a tougher nut to crack due to intrinsic geometric coupling. The authors openly acknowledge this and frame it as a direction for refinement: a more tailored hoop-strain projection or a different stabilization strategy might unlock even tighter control over εθ. This isn’t a flaw; it’s an invitation. It signals that the axisymmetric VEM is not a finished statue but a living framework, ready to be tuned as new materials, new geometries, and new loading scenarios push the envelope. The study’s conclusion hums with that spirit: the method is complete enough to be trusted now, and flexible enough to improve as the challenges evolve.

In the end, what makes this work memorable isn’t a single clever trick, but a deliberate synthesis of geometry, mathematics, and engineering pragmatism. The axisymmetric axis is not just a coordinate choice; it’s a way of aligning computation with the physics of spinning, cylindrical solids. The boundary-driven projection keeps the interior light-footed and the computation lean, while the radial weighting preserves fidelity to volume — the heart of how real materials store energy under pressure and heat. For curious readers who enjoy a story about how a field moves from theory toward real-world impact, this study is a crisp example of how careful mathematical craftsmanship translates into better tools for engineers building the next generation of safe, efficient, and reliable axisymmetric structures. And it’s anchored by a real institution — the Escola Politécnica of the University of São Paulo — with authors who bring both mathematical depth and a sense of practical purpose to the table.

Lead researchers Paulo Akira F. Enabe and Rodrigo Provasi, Escola Politécnica, University of São Paulo, guided a team toward a framework that respects axisymmetric physics while embracing the computational flexibility of polygonal meshes. The result is a robust, scalable approach that could accelerate how engineers simulate cylinders, shells, and vessels across industries, from energy to aerospace to chemical processing. The axisymmetric VEM isn’t just a step forward in numerical methods; it’s a doorway to more accurate, more adaptable analyses of the spinning, curved worlds that define much of modern engineering.