A Big Challenge for Soft Robots

Soft robots promise a gentler touch, resilience to impact, and a kind of adaptability that rigid machines can only envy. But as these squishy machines scale from cute centimeter toys to meter-long tools for real work, control stops being a neat afterthought and becomes the whole game. Pneumatic actuation—blasting air into pliable chambers to bend, twist, or push—works beautifully on a small scale, yet the moment you try to coordinate dozens of chambers across several meters, the air itself becomes a choreography that’s easy to botch. Pressure lags, volume changes, leaks, and the way air flows through one joint can ripple through the entire limb. In short: scale up soft robots, and you don’t just need bigger muscles—you need smarter nervous systems.

That intuition sits at the heart of a project from Brigham Young University’s Robotics and Dynamics Laboratory in Provo, Utah. The BYU team—led by Marc D. Killpack, with contributions from Curtis C. Johnson, Daniel G. Cheney, and Dallin L. Cordon—built a system that treats pressure control like a distributed, high-speed nervous network rather than a single central pump. Their goal was threefold: enable high-flow, high-pressure actuation for large soft robots; keep control local and robust over long physical distances; and do all of this with affordable parts and open-source software. The result is PneuDrive, a modular pressure-control system designed to run like a well-oiled highway for air, with smart traffic signals that keep every valve in sync even when the robot stretches across a room.

Why does this matter beyond the thrill of engineering neat hardware? Because the same reasons soft robots excite researchers—safety, adaptability, and the potential to work next to humans or fragile objects—depend on reliable, real-time control when the robot is large enough to matter in the real world. If you want soft robots to help lift, assemble, or handle unpredictable things, their brains have to keep pace with their bodies. PneuDrive is a bold step toward that pace, offering a practical, scalable platform that others can use as a foundation rather than reinventing the wheel for every new limb. The project doesn’t just solve a niche problem; it tries to unlock a scalable approach to soft robotics that could ripple through research and real-world applications alike.

PneuDrive: A Highway of Tiny Controllers

Imagine a highway where dozens of traffic signals coordinate dozens of lanes in real time. That’s the mental picture behind PneuDrive’s hardware: a daisy-chained RS-485 bus runs through a string of embedded boards, each one a tiny hub that directly controls up to four valve/chamber pairs. The system is purpose-built for “big” soft robots—meters long with many pressure inputs—yet the hardware is deliberately simple and rugged enough to survive a lab floor or a workshop.

The core idea is to distribute the control load. Up to four embedded boards can share a single bus, and the bus itself can stretch over more than ten meters with robust protection against electrical interference, electrostatic discharge, and surges. Each embedded board has four valve drivers, a microcontroller, and a few analog sensors. They’re designed to be powered by a common 10–28V DC supply, but the real magic is how they talk to the outside world: a two-wire RS-485 line that can carry a flurry of commands and data while staying reliable in a noisy lab environment. Each board gets a unique address via an address-select switch, enabling a scalable tree of devices without a spaghetti of wires.

Communication follows a careful, disciplined protocol. The bus is half-duplex and uses a simple five-16-bit-integer packet structure for each talk. The controller sends pressure commands to a targeted device, and the addressed device responds with its current pressure data. A clever “auto-direction” scheme—borrowed from existing IC design—ensures only one device talks at a time, preventing the dreaded bus collisions that can corrupt data and stall a control loop. In practice, this system can support a real-time loop that flicks air pressures across 12 channels with a cadence fast enough to feel instantaneous to a dynamic soft limb.

On the practical side, the boards aren’t power hogs. They pull from a compact buck converter that feeds a 3.6-amp rail, with separate 5V logic and a dedicated 5V analog supply for pressure sensors. The electronics are built around off-the-shelf components and standard SBCs (single-board computers) like Raspberry Pi variants or ODROID devices, so researchers can drop in a familiar brain and keep the rest modular. The software side mirrors that philosophy: a ROS node by default for robotics workflows, plus a Python API that makes it easy to script experiments without getting mired in middleware. The result is a platform that invites other laboratories to replicate, extend, or remix without paying a heavy toll in custom hardware.

Real-world hobbyhorse of any robot project: practical, affordable, and open. The PneuDrive hardware is described as about $200 per embedded board, and the authors provide open-source designs and software to help others build their own distributed pressure-control networks. The combination of a low price tag and a flexible, distributed topology is what could turn a clever prototype into a widely used tool in soft robotics research and education.

Three Ways to Model the Pressure Dance

If you can flood a soft robot with air, you also need to predict what that air will do as the joint flexes, the limbs bend, and the environment pushes back. PneuDrive isn’t content with a single “best guess” model; instead, the researchers provide a modeling toolkit with three distinct dynamic models. Each one trades off realism, speed, and ease of use, so researchers and engineers can pick the right tool for the job, or compare them to learn which features matter most in a given task.

The first model is the linear one. It’s a first-order differential equation that ties the rate of change of pressure to a weighted combination of the current pressure and a commanded pressure. It’s simple, fast, and surprisingly robust for certain regimes, especially when the system’s dynamics aren’t dominated by rapid, nonlinear effects. But it also hides a critical truth: in a large soft robot, the joint-space dynamics and the input dynamics couple in ways that a purely linear picture cannot capture.

The second model is nonlinear and more faithful to physics. It starts from first principles and keeps track of volume changes, mass flow, and nonlinear flow regimes. The mass flow equations hinge on the effective area of valves and the pressure difference across them, which broadens the model to accommodate how air actually moves through a system with many chambers. It also includes a term to account for volume-model uncertainty, which matters when a soft joint isn’t a rigid cylinder but a squishy chamber whose volume changes as it bends. Practically, this model can follow complex transients far more accurately than the linear version, albeit at a higher computational cost.

The third model takes a different route: a parametric approach. It borrows from physical intuition but introduces free parameters that let the model bend to real data. In other words, it’s not trying to be a perfect reflection of physics; it’s tuned to capture the observed input–output shapes. This makes it adaptable and often surprisingly good at matching actual hardware, even when the underlying physics gets messy. However, the authors note that optimization to fit these parameters isn’t always stable or repeatable—about a tenth of runs produced usable models in their tests.

To empower users of PneuDrive to compare these options quickly, the team built a modeling toolkit with a Python module for each model type and a Jupyter notebook that pairs parameter identification with real data. They even wired in an LM-fitting library so practitioners can dial in parameters for their own hardware and then use the resulting models for open-loop prediction or closed-loop control simulations. It’s not just a gizmo; it’s a little lab in a box that helps you decide whether speed, accuracy, or simplicity matters most for your robot—and then gives you the tools to test that choice in real time.

What the Experiments Show About Real-Time Soft Robots

To move from concept to credibility, the BYU team put PneuDrive through a set of hardware experiments designed to stress-test both the controller and the models. They started with a four-chamber, single-joint test rig to examine step response and trajectory-tracking performance. The results were striking: the closed-loop control using a straightforward proportional command tracked pressure targets with smooth, repeatable behavior across trials. The hardware showed the expected variations between chambers, a natural consequence of manufacturing tolerances and the odd coupling that arises when soft chambers influence one another as they inflate and deflate. Importantly, the team didn’t pretend every chamber behaved identically; they used the variability to motivate the need for robust modeling and adaptive control.

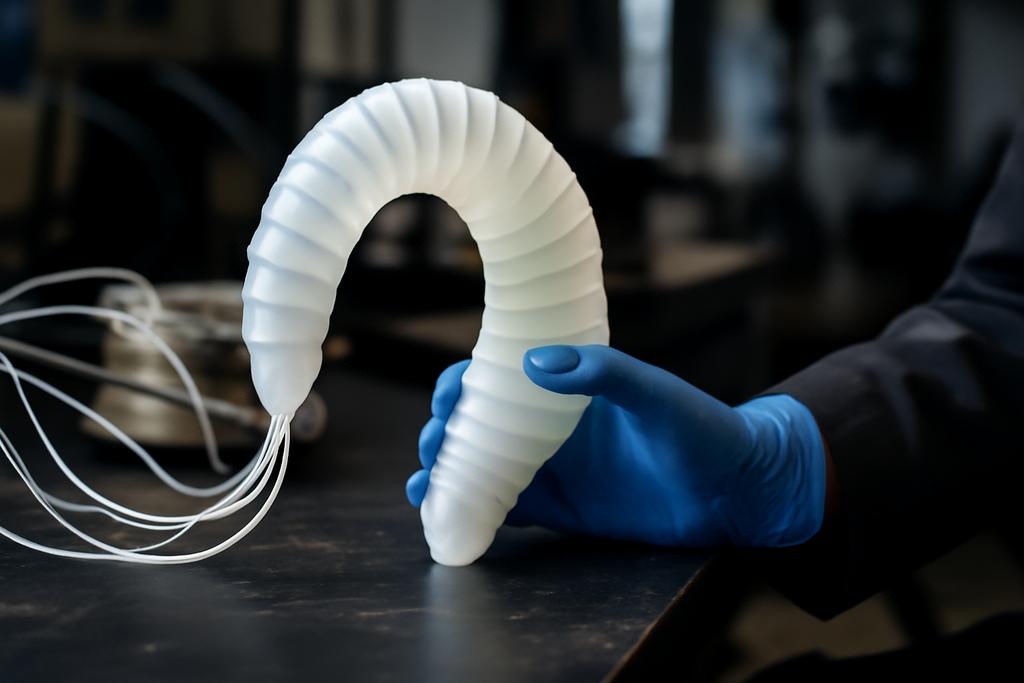

Next came a larger demonstration: a 1.16-meter-long, three-joint soft arm with twelve pressure chambers, each controlled by a dedicated portion of the PneuDrive network. This experiment wasn’t just a party trick; it proved that distributed, pressure-based control could scale up to a real soft robotic system, with the arm following a smooth trajectory commanded in pressure space. The “open air” of the workspace—where the robot interacts with its environment—began to resemble the kind of messy, dynamic tasks soft robots would actually perform in the wild, from manipulation to safe contact with humans or objects.

But the true value of the work lies in the modeling toolkit and the insight it yields about what kind of model to use when. The team gathered 20,000 data points for training and 2,000 for validation per chamber, then ran multiple optimization attempts for each model type. Remarkably, each optimization finished in under a second, making it feasible to generate distinct parameter sets for each chamber on the fly or to refresh them as hardware ages or tolerances drift. Across the validation data, the nonlinear model generally offered the best predictive fidelity, capturing transients without sacrificing too much steady-state accuracy. The linear model, by contrast, remained the fastest to compute and was consistently stable, offering a practical option when speed is paramount and some loss of precision is acceptable. The parametric model sat in between: easy to fit and workmanlike in many situations, but not as reliably convergent as the nonlinear model. In short, the toolkit makes the trade-offs explicit, turning a single robot into a family of models you can compare in a principled way.

In the end, the authors emphasize a practical takeaway: for a given large-scale soft robot, you should expect to trade off accuracy, speed, and ease of system identification. The nonlinear model often wins on accuracy for real-time control, but it comes at the price of computational overhead and more involved data treatment. If you need rapid iteration or real-time planning on modest hardware, the linear or parametric models can be golden. The modeling toolkit provides the means to quantify those trade-offs with real hardware data, rather than relying on clean but ultimately unrealistic simulations.

What This Could Change About the Future of Soft Machines

The immediate punchline is practical: a scalable, open, low-cost platform for controlling large-scale, pneumatically actuated soft robots. The system’s distributed architecture is what makes meter-scale soft robots plausible in the wild, not just in the lab. By letting each chamber be smart and speak on a shared highway, PneuDrive reduces wiring complexity, minimizes centralized bottlenecks, and sets a blueprint for how future soft robots could be deployed outside of controlled testbeds.

Equally important is the modeling toolkit. The field has long wrestled with how to simulate pneumatic actuation in real time—enough fidelity to be useful, but not so heavy that it stalls learning loops or model-predictive controllers. By offering three distinct models, plus an easy path to parameter identification with real data, the authors give researchers a principled way to choose how to model actuation based on the task. This matters for model-based control, reinforcement learning, and any approach that relies on reconstructing how a soft robot will respond to a given command before actually trying it.

Beyond the technical specifics, the project hints at a broader shift in robotics culture: open hardware and open software as accelerants for discovery. The BYU team emphasizes not just the engineering novelty but the accessibility of the system—the cost, the modularity, and the available code and designs. If more labs adopt a similar posture, we could see a wave of collaborative, cross-pollinating progress in soft robotics, where researchers focus less on bespoke rigs and more on shared building blocks that scale in both complexity and capability.

There is a human side to this leap as well. Large soft robots could one day operate alongside people and delicate works—handling prosthetics, assisting in rehabilitation, or enabling safer exploration in cluttered environments. The pressure-control backbone that PneuDrive provides may be the quiet engine behind that future, keeping air and motion aligned when the stakes are high and the room is full of unknowns. And because the work sits at the intersection of hardware, software, and modeling, it invites a broader community of designers, educators, and curious tinkerers to push the boundaries without reinventing core components every time.

In the end, the story of PneuDrive is a story about making a clever idea practical. It’s not a single breakthrough, but a careful, scalable engineering solution that answers a stubborn question: how do you keep a soft robot responsive, safe, and predictable when its muscles aren’t just big, but many? The Brigham Young University team’s answer—distributed pressure control, a flexible software stack, and a modeling toolkit you can actually use—offers a vivid vision of how soft robotics could mature from experimental novelty to real-world utility.

For readers curious to see the results in motion, a video summarizing the results is linked in the project materials and demonstrates the arm tracing a smooth trajectory under the three-model framework. The work is a collaborative effort from Brigham Young University’s Robotics and Dynamics Laboratory, with Curtis C. Johnson, Daniel G. Cheney, Dallin L. Cordon, and Marc D. Killpack among the contributing authors. The researchers’ goal is clear: give large-scale soft robots a reliable, accessible, and tunable control core, and then let the rest of the plant grow around it.

In short, PneuDrive isn’t just about air and valves. It’s about building a scalable nervous system for a new generation of soft machines, one that can listen, react, and learn in real time as they stretch toward real-world work. If the next few years bring more labs embracing distributed control, smarter actuation models, and open tools, soft robots might finally step out of the lab and into everyday life with a quiet, confident pulse of air guiding their every move.