Building the Future One Layer at a Time

3D printing, or additive manufacturing, has revolutionized how we create objects—from intricate aerospace parts to custom medical implants. But beneath the surface of this seemingly magical layering process lies a complex dance of physics and mathematics. How do you design a structure that not only performs well once built but also survives the very act of being built? This question is at the heart of research from the University of Regensburg, where Luise Blank and Maximilian Urmann have developed a new mathematical framework to optimize multi-material 3D printed structures that can support their own weight during construction.

The Hidden Challenge of Overhangs

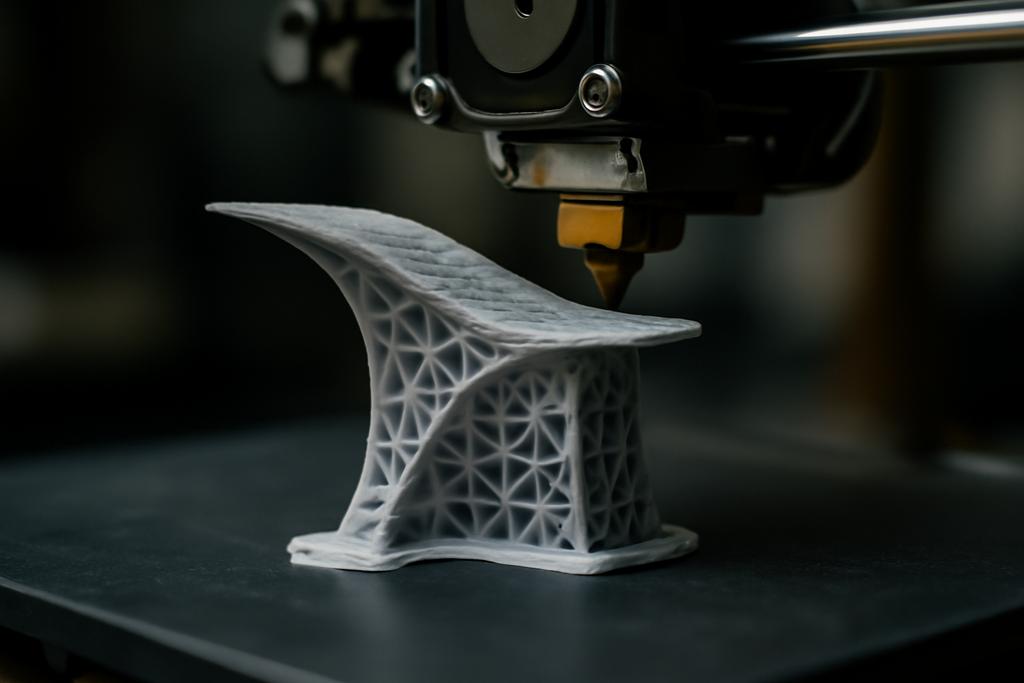

Imagine printing a delicate bridge or a cantilevered beam. Gravity pulls on every layer as it’s deposited, and unsupported overhangs can sag or collapse before the print is complete. Traditionally, engineers have tackled this by adding temporary support structures—extra material that props up the print but must be removed later, adding cost, waste, and risk of damage.

Blank and Urmann’s approach sidesteps this by embedding the construction process itself into the design optimization. Instead of just focusing on the final shape, their method penalizes deformations caused by gravity during the build. The goal? To create designs that are inherently stable throughout the printing process, reducing or even eliminating the need for supports.

Phase Fields: Blurring Boundaries to Sharpen Designs

At the core of their method is a mathematical tool called the phase field approach. Unlike traditional methods that sharply separate materials and voids, phase fields allow for smooth transitions between different materials and empty space. Think of it like a watercolor painting where colors blend softly rather than harshly defined edges. This flexibility enables the algorithm to explore a vast design space, including complex topologies and multiple materials, without getting stuck on rigid boundaries.

In practice, the phase field is a vector function that assigns a fraction of each material at every point in the design domain. The researchers consider multiple materials plus void, allowing for sophisticated multi-material structures that can be tailored for strength, flexibility, or other properties.

Modeling the Build Process Layer by Layer

3D printing builds objects layer by layer, and the team models this by considering the structure as it grows in height. At each stage, they solve elasticity equations to predict how gravity will deform the partially built object. This requires careful mathematical treatment because the domain changes as the object grows, and the material properties can even harden over time as layers cure.

They introduce a cost functional that balances three competing goals: minimizing the structure’s compliance (a measure of flexibility under load), penalizing deformations during construction, and controlling the smoothness of material interfaces. By adjusting weights on these terms, designers can prioritize stability during printing or final performance.

Mathematics That Holds Up Under Pressure

One of the paper’s key achievements is proving that their optimization problem is well-posed. This means that solutions exist, are stable, and can be found reliably by numerical methods. They extend classical inequalities like Korn’s inequality to domains that grow with the build height, ensuring that the mathematical foundations remain solid even as the structure evolves.

Moreover, they show that their cost functional is twice differentiable in a suitable function space, which is crucial for applying efficient gradient-based optimization algorithms. This differentiability allows the use of advanced solvers that can handle millions of variables, a necessity for realistic 3D printing problems.

From Theory to Computation: The VMPT Method

To solve the complex optimization problem, the researchers employ a variable metric projection type (VMPT) method. This is an advanced gradient-based algorithm adapted to the infinite-dimensional setting of function spaces. It iteratively updates the material distribution while respecting constraints like fixed material volume and phase field bounds.

They enhance the solver with second-order information—akin to using curvature in optimization—to speed convergence. Additionally, a nested approach refines the mesh and layer discretization progressively, starting from coarse approximations to fine details. This strategy dramatically reduces computational time without sacrificing accuracy.

Numerical Experiments: Stability in Action

The team tested their method on classic structural problems like cantilever beams and MBB beams, both in two and three dimensions. Their results show that including the construction phase in the optimization leads to designs with fewer and smaller overhangs, more vertical supports, and mass distributed closer to the build plate. These features reduce deformation during printing, enhancing stability.

They also explored multi-material designs, where stiff and soft materials are combined strategically. For example, softer materials can be used in regions that need to absorb stress during printing, while stiffer materials form the main load-bearing structure. This multiphase approach even allows for optimizing removable support structures as an additional material phase, balancing material usage and ease of post-processing.

Why This Matters: Toward Smarter 3D Printing

Blank and Urmann’s work pushes the frontier of additive manufacturing by integrating the physics of the build process directly into design optimization. This holistic view promises to reduce reliance on support structures, lower material waste, and enable more complex, reliable prints.

Beyond manufacturing, their mathematical framework offers insights into how materials can be distributed and combined to meet competing demands of strength, flexibility, and manufacturability. It’s a step toward truly intelligent design systems that understand not just what a structure should do, but how it should come to life.

Looking Ahead

While the computational demands are significant—some 3D examples involved millions of variables and hours of CPU time—their solver’s scalability and convergence properties are promising. Future work could integrate more realistic material behaviors, thermal effects, or even real-time feedback from printers.

In a world increasingly shaped by additive manufacturing, such mathematically rigorous and computationally efficient tools will be essential. They help ensure that the objects we print don’t just look good on paper but stand strong in the real world, from the first layer to the last.

Research by Luise Blank and Maximilian Urmann at the University of Regensburg.